The A200S is one of the smallest high current/voltage motor controllers available (110x40x28mm). Yet it packs a serious punch!

The A200S was designed specifically for use in Featherweight and Heavyweight combat robots. It runs the extremely popular VESC®*-Project firmware.

Heavyweight Weapon - Triforce (Blue)

2x 12S A200S running HFI with XAG A40 motors for weapon

Quick tips on setup

!!ONLY USE 1 BEC, cut the 5v wire on all but one or the BEC can be damaged!!

Max battery cable length without additional capacitors is 1m (Battery wires should be short, thick and grouped together, motor wires should be long. So best to place controller near battery with long wires to wherever the motor is located.)

Please be careful when programming settings. Start at low currents and work up. Setting everything at max during initial setup is a bad idea.

We recommend detecting motors using the FOC motor setup wizard. This will automatically find the correct settings for your motor. If you have problems getting your particular motor setup please contact us and we will do our best to help.

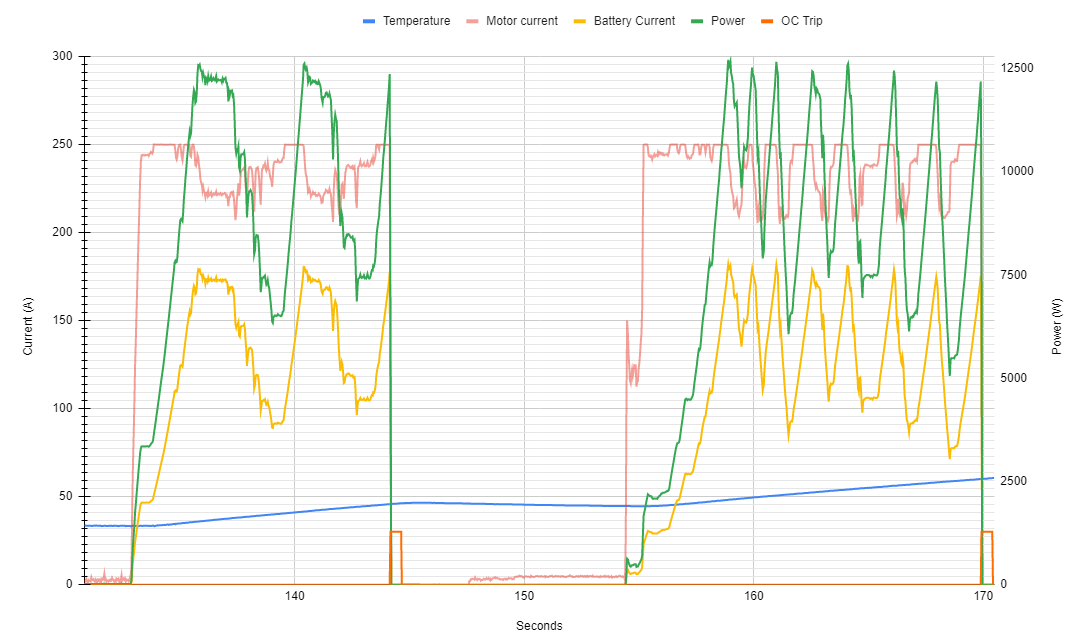

If you experience overcurrent faults a lot your motor is badly tuned. Just turning up the abs max current setting is not a good solution as you are only masking the root of the problem. Please contact us for help with this.

High voltage LiPo is extremely dangerous if handled incorrectly. ALWAYS run with a fuse, especially for testing. A loop plug is an easy way to disconnect the batteries in case something goes wrong.

Current Handling

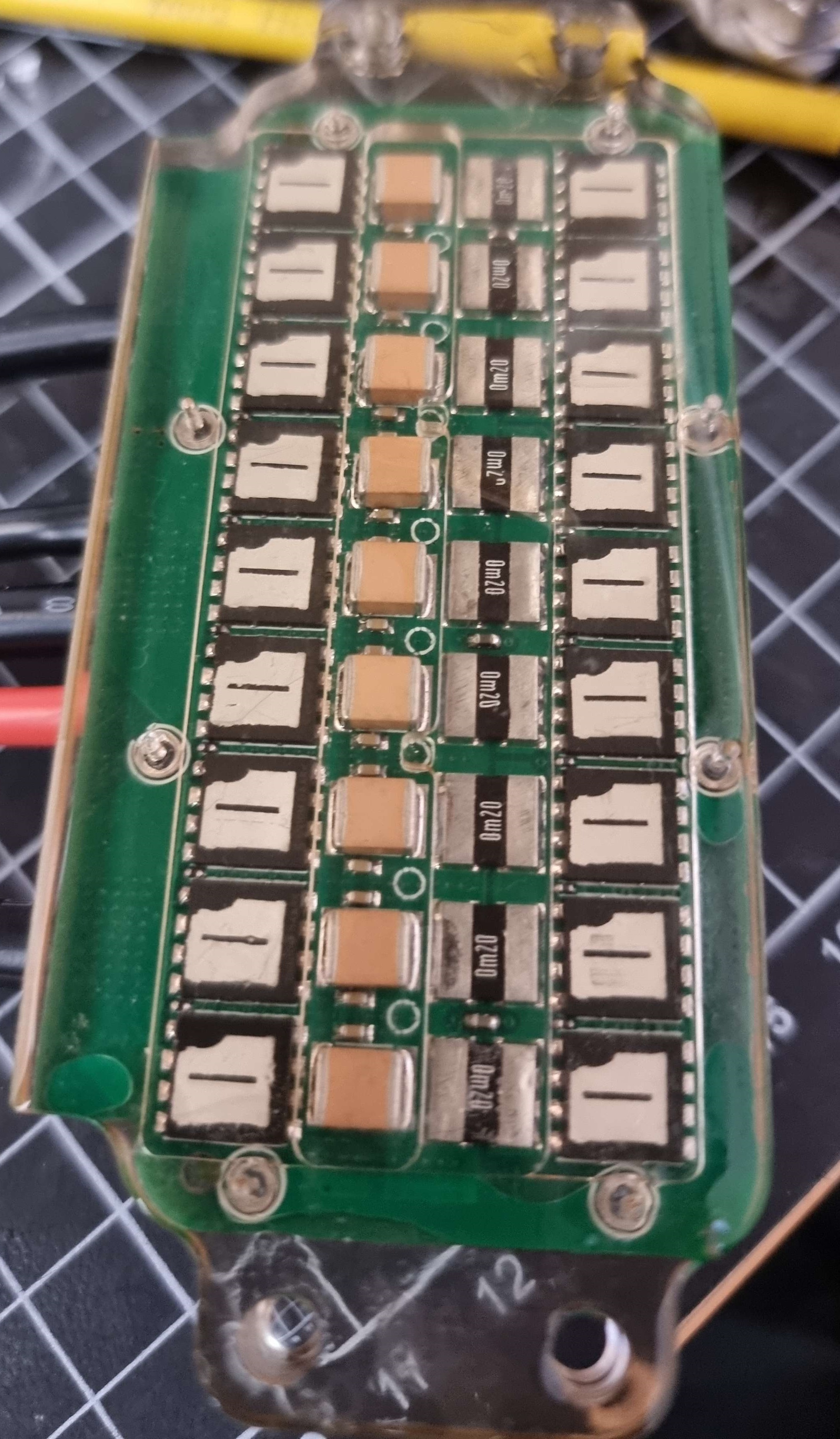

- 18 FET design using modern OnSemi NTMTSC1D6N10MCTXG mosfets

- 300A Motor Burst

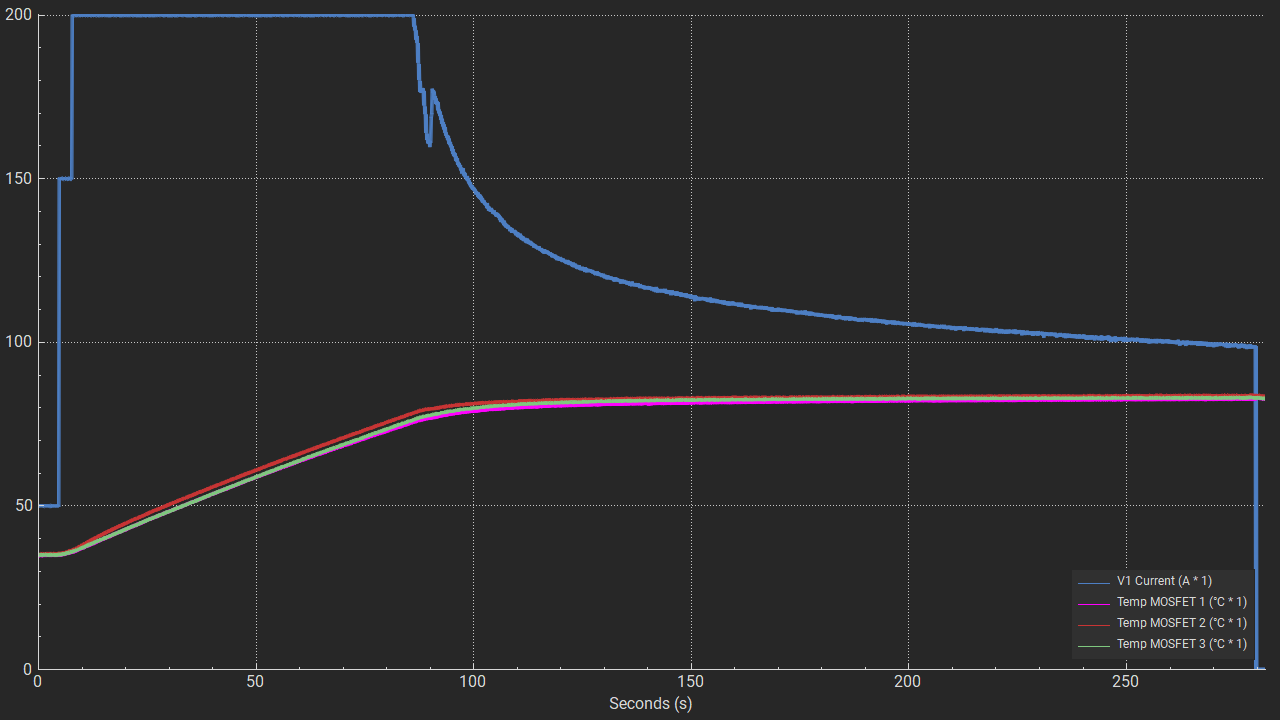

- 200A Motor for 80s without thermal throttling, with no additional cooling

- Approx 100A continuous, with no additional cooling

- Max battery current 180A (3x XT60 parallel)

- Double pulse tested to 90V 700A

- Dyno tested to 18S 250A

- Hardware overcurrent trips at 440A Mosfet Channel, 380A Body diode (Reverse recovery)

Mechanical Features

- Weight: ~330g with standard wire set

- Dimensions Overall: 111x48x30mm

- Mounting pattern: 4x M4, 101x18mm

- Battery connection wire length: 10cm

- Motor connection wire length: 30cm

- 6061-T6 CNC Machined Aluminium, black anodised heatsink.

- MJF 3D printed Nylon 12 case

- 8x M2 A4 stainless bolts

Electrical Features

- CANBus

- Voltage filters, 3 low side shunts

- IMU

- 3mm FR4 TG170 8Layer 3OZ PCB

- EFuse Protected supply outputs

- 12V 1.2A

- 5V 1.0A

- 3.3V 0.5A

- I/O protected by TVS

- USB can be used to power logic for offline programming

- Logic can be powered from extra AUX Power input 12-48V, 0.8W idle

Electrical Connections

-Power/Motor Connections

- Triple 12AWG silicone input cables with XT60 (should be connected in parallel)

- 8 AWG silicone output cables with 6mm Lugs

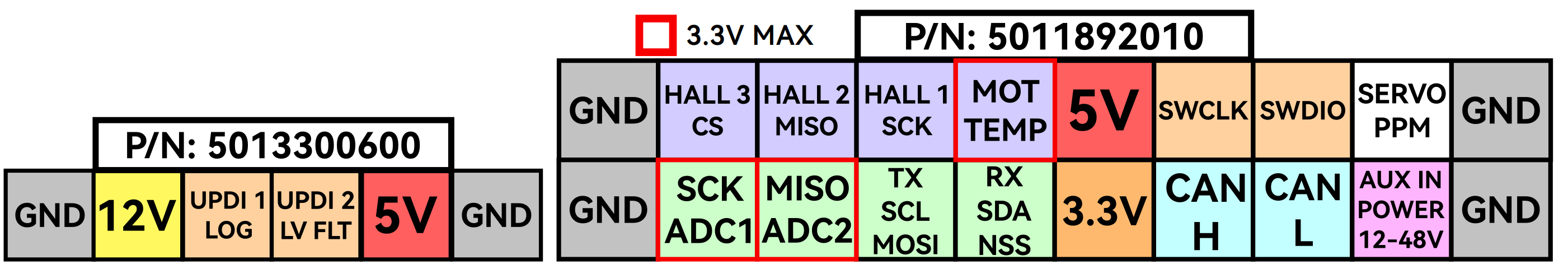

-Logic connections

- All in one 20pin Pico-Clasp locking connector provides all standard interfaces - PPM, CANBus, ADC, UART, Hall sensors, 5v, 3.3v, SPI, Buttons, Encoder, Motor Temperature, Aux power input (12-48V), SWD Programming.

- 6 Pin Picoclasp locking connector for 12V Switchable Aux output, 5V, programming inbuilt ATTiny3216 and ATTiny1616.

- SD Card slot for logging at up to 80Hz.

- USB Type C for connection to VESC-Tool

Motor Commutation Modes

- FOC - Sensorless, Hall Sensors or Encoder

- BLDC - Sensorless, Hall Sensors or Encoder

- DC - For driving brushed DC motors on outputs A and C.

Motor Control Modes

- Current - Controls current to motor irrespective of duty cycle

- Duty Cycle - Controls duty cycle sent to motor irrespective of current

- PID RPM control - Controls motor RPM using a PID loop

Control Interfaces

- PPM

- ADC - For use with analogue throttles, supports cruise control and reverse

- UART - For PC control using VESC®* Tool and custom applications

- CANBus - For custom applications, also supports slaving controllers and traction control

Voltage Rating

- 8-80v, 18 cell LiPo maximum.

Safety Features

- Software over current protection

- Slow temperature cutoff

- Battery voltage cutoff

- Hardware overcurrent protection

Programming features - using VESC®* Tool

- Adjustable current limits, Battery and Motor current are independently controlled

- Adjustable voltage limits

- Adjustable RPM limits

- Adjustable Power limits

- Adjustable duty cycle limits

- Adjustable regenerative braking

- Adjustable throttle curves and ramping time

- Real time and Sampled Data monitoring and graphing

- Automatic motor detection and tuning.

- LiSP scripting support for custom functions

- ATTiny3216 with SD card for logging and hardware overcurrent protection

- ATTiny1616 for controlling external voltage outputs and hardware overcurrent protection

HW Overcurrent testing

High density power stage with very low inductance DC link

Constant current testing 200A for 80s. Appox 100A continuous

The A200S runs the popular VESC®*-Project firmware by Benjamin Vedder.

* VESC is a registered TM, owned by Benjamin Vedder

2 Reviews Hide Reviews Show Reviews

-

A200S V4.1 Foe eFoil

I use it in an eFoil for 5 moths now. Run it with 14S LiIon. Motor is a 6kW 16 pole inrunner. Cooling is done passively on a 400g aluminium heat sink. Still running FW 6.2. After dialing in motor parameters it runs really smooth. It stays also cool, never got over 50C degrees C even with 180A phase and 120A battery current (for some seconds). I normally run it at around 60A phase 100A motor continously, mosfet temp stays below 40C. It’s not cheap but very well made, much better than the cheap chinese vescs. Support from Euan is also great. ? Daniel

-

Good ESC

it works as it should!